Process

Start

Sourcing Raw Material

Raw Material Segregation

Melting Process in Induction Furnace

Quality Check

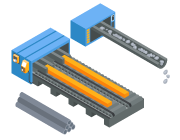

Continuous Casting Machine (CCM) & Billet Manufacturing

Rolling Mill Roughing

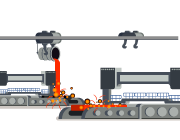

Quenching & Self Tampering

Quality Check

Automatic Cooling Bed

Automatic Bending / Bundling

Strapping & Tagging

Stocking

Dispatch

End

Manufacturing Process of SUNTECH TMT Bars

Steel billets (typically Mild

Steel

and

Recycled-Scrap) are reheated to ~1200°C in a furnace, then rolled through sequential

stands (roughing → intermediate → finishing mills) to achieve the desired ribbed profile

and diameter (8–25mm). The hot bars undergo thermo-mechanical treatment (TMT) via

high-pressure water quenching, instantly hardening the outer layer into martensite while

the core remains austenitic. Residual heat self-tempers the surface, followed by

atmospheric cooling on a cooling bed to transform the core into ductile

ferrite-pearlite. Finally, bars are cut to 40ft. lengths, tested for strength/bend

compliance, and bundled for dispatch. This process yields high-strength,

corrosion-resistant SUNTECH TMT bars (e.g., Fe-500/550D grades) ideal for reinforced

concrete structures.

Key Stages:

Billets → Heating → Rolling → Quenching → Self-Tempering →

Cooling →

Cutting → Testing → Bundling